3D Printing 2000+ face SHIELDS:

We had a video about our face shield production in the local news

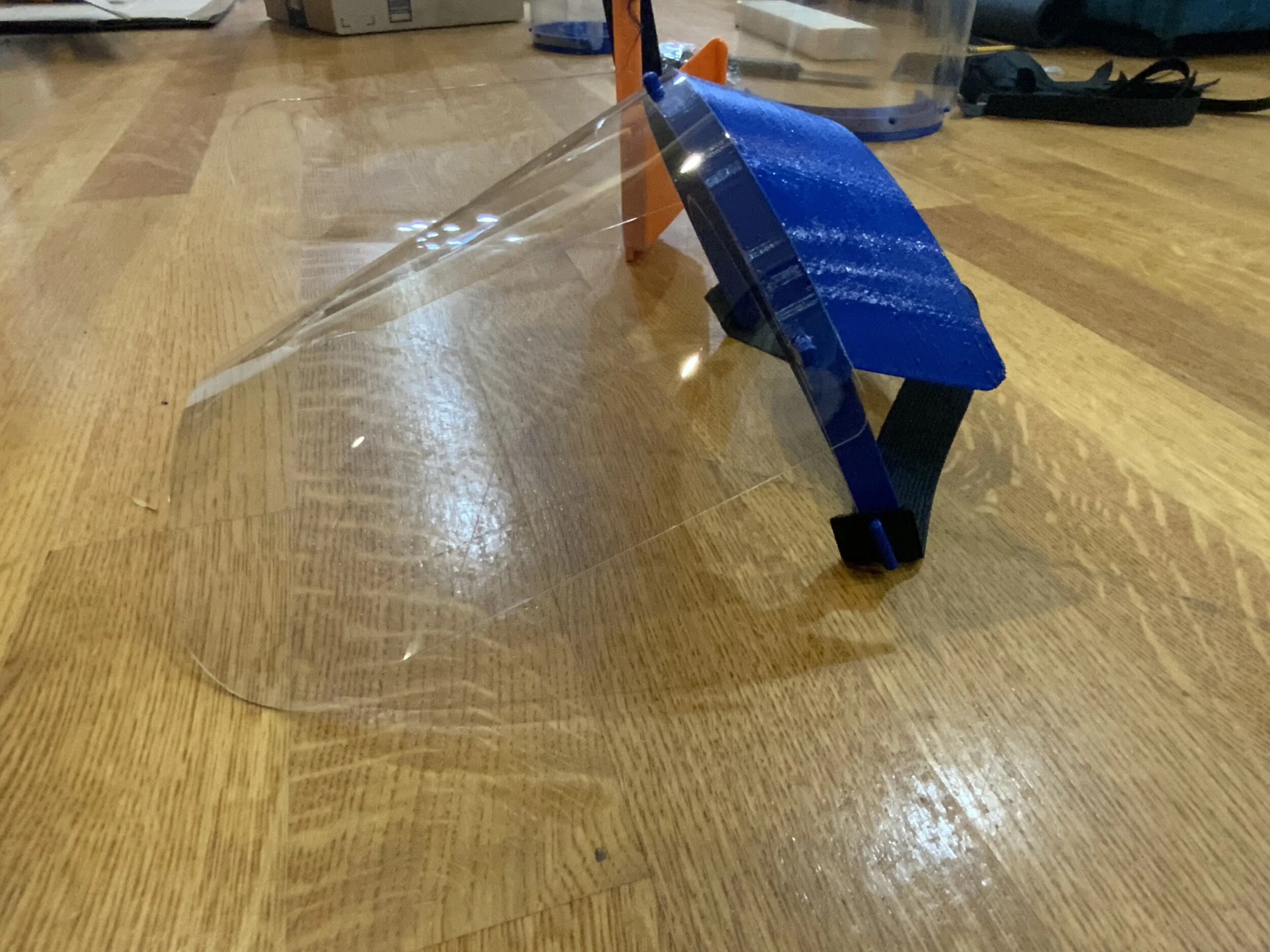

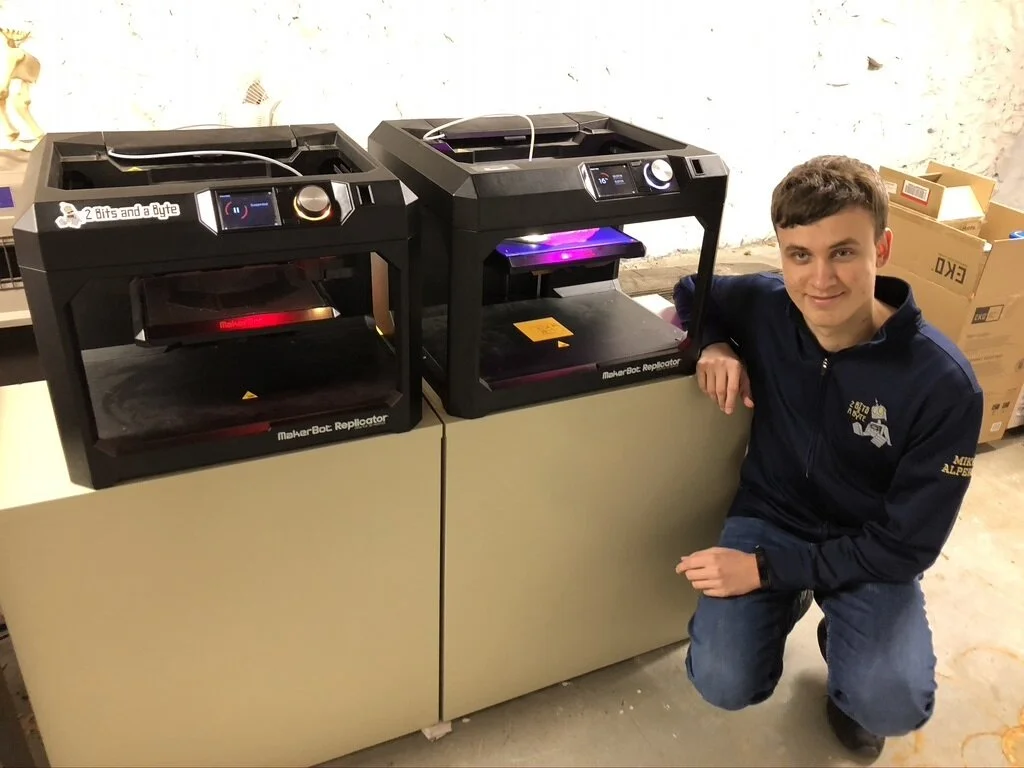

The pandemic caused a major shortage of personal protective equipment. So, I worked with my robotics team to 3D print over 2000 face shields. This involved the team members’ personal 3D printers, and we also got permission to borrow the my high school’s 3D printers and filament supplies. (These would have otherwise been unused, since school was in lockdown)

Twelve of us were running our printers continuously since school lockdown and throughout the summer. One of my teammates has a laser cutter, so we brought the 3D printed frames to him. He cut out the transparent plastic sheets for the front visor, and added the elastic straps. Finally, I picked up the assembled face shields and brought them to a makerspace in Lowell, which sanitized them and delivered them to local hospitals.

The demand for face shields eventually fell because hospitals created facilities to resterilize existing PPE. When this happened, we shifted our production to helping our school staff, printing 1000 shields for Lexington Public Schools, customized with our logo.

LexHACK - 150+ member ONLINE HACKATHON:

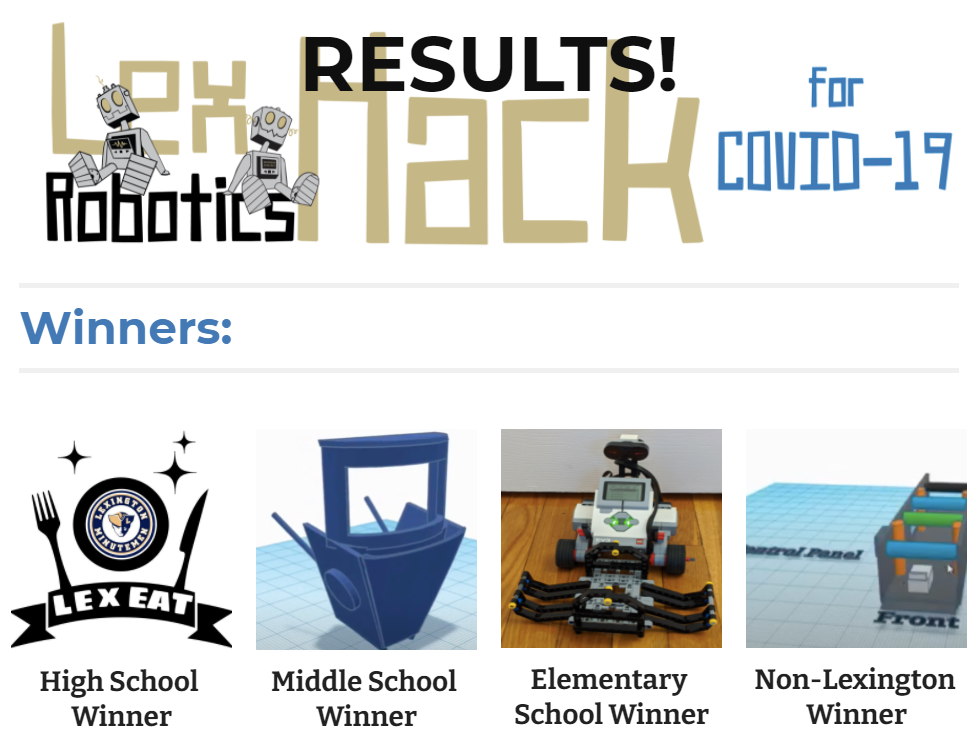

This was an outreach event my robotics team did in lockdown. To promote STEM learning while school was in lockdown, we organized a townwide virtual hackathon. The hackathon focused on solving problems the pandemic posed to our community.

We started by creating a website, and reaching out to Lexington schools and parent-teacher associations to attract participants. We eventually had over 150 students, from as young as kindergarten to seniors in high school. Over 1/3 of our participants were female, and half had little to no programming experience.

During the event the robotics team provided individual support to participants as they worked on their projects, to make sure everyone was able to bring their ideas to fruition. We created a rubric and judged the submissions with the help of the school superintendent, school committee and select board members.

The submissions that we received included package-disinfecting robots, new face shield designs, apps to coordinate remote learning, games to encourage social distancing, and more. More details about the hackathon are visible on the website we created: https://sites.google.com/lexingtonma.org/lexhack2020/

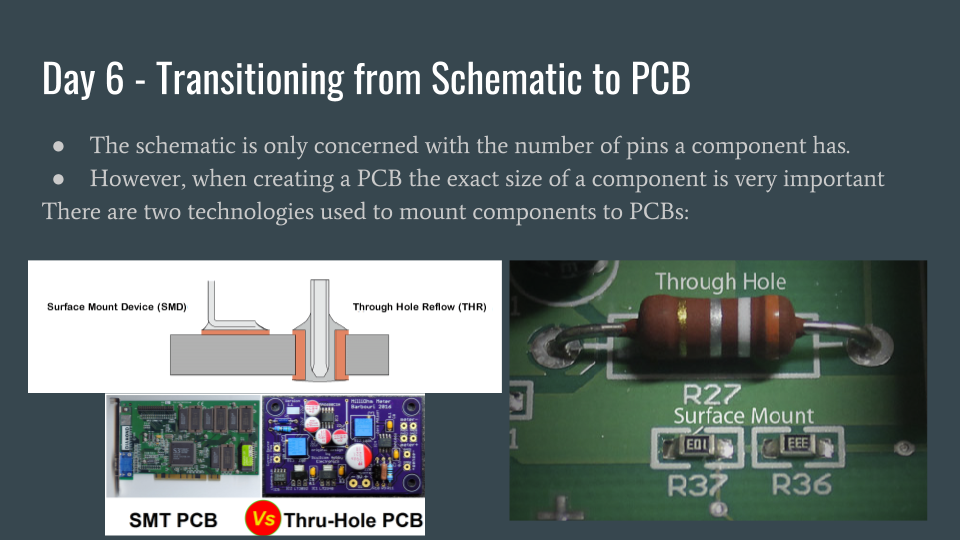

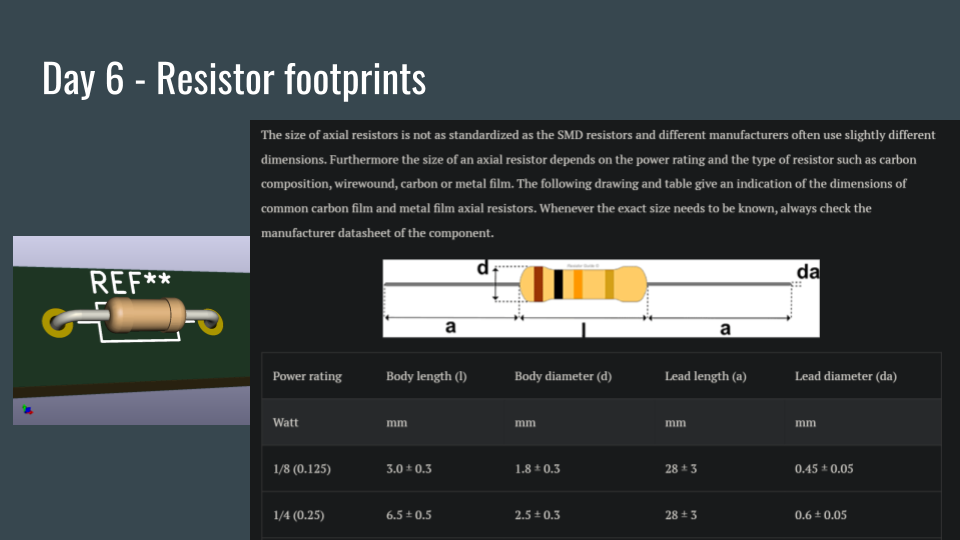

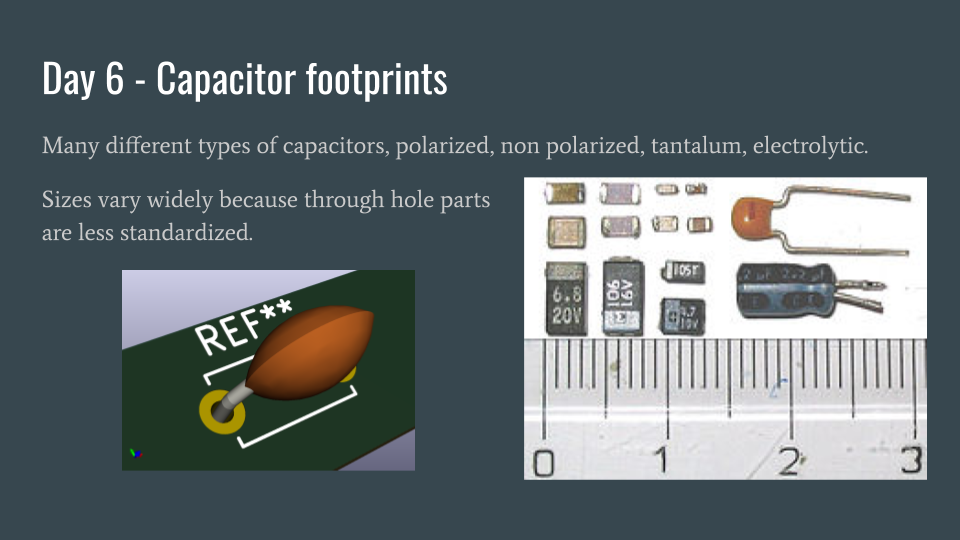

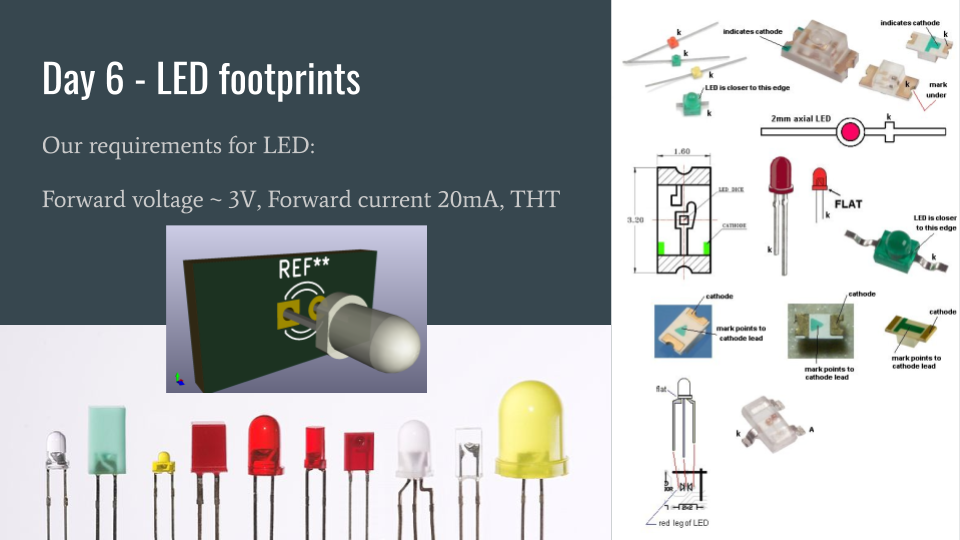

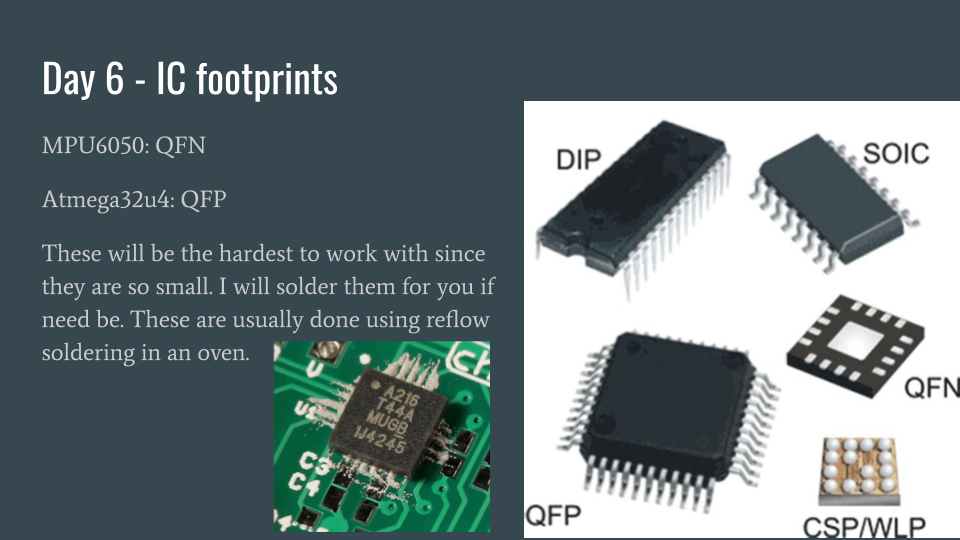

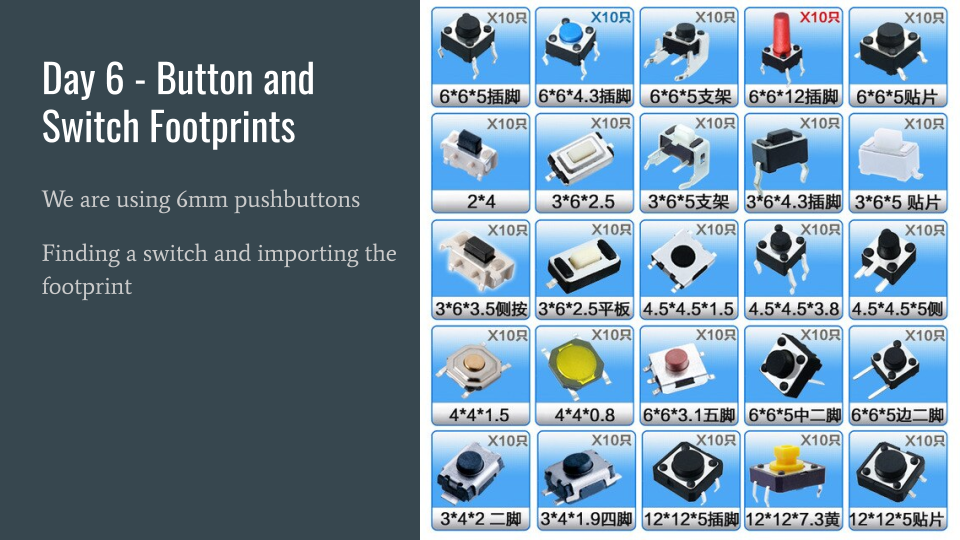

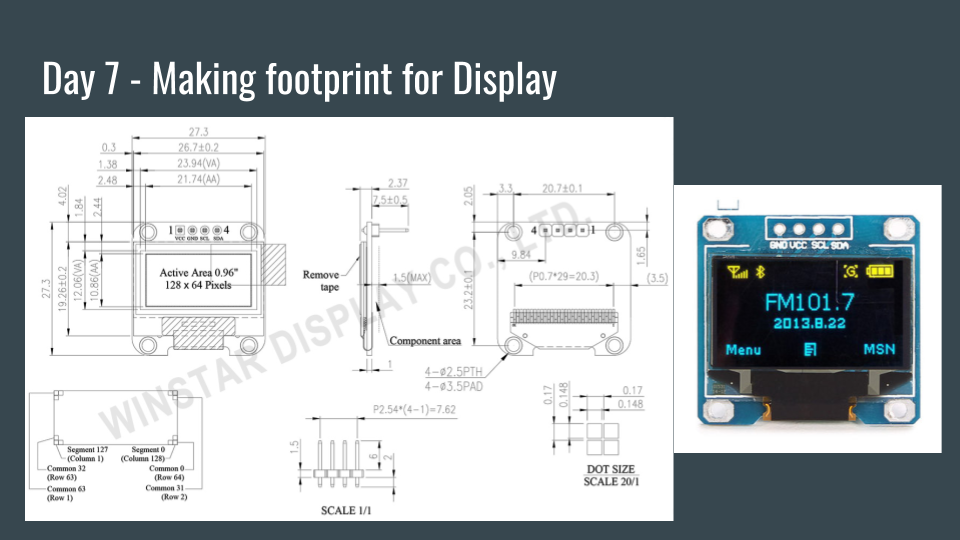

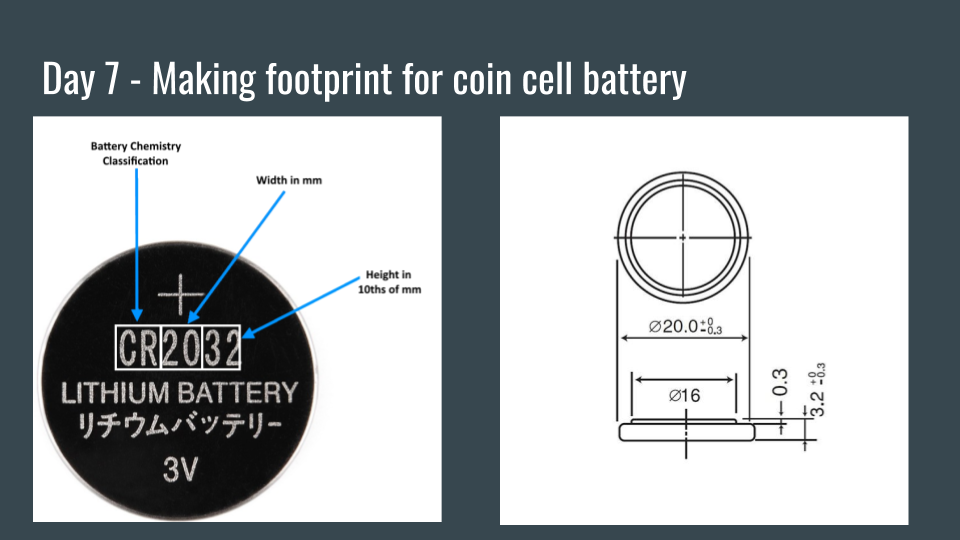

PRINTED CIRCUIT BOARD DESIGN CLASS:

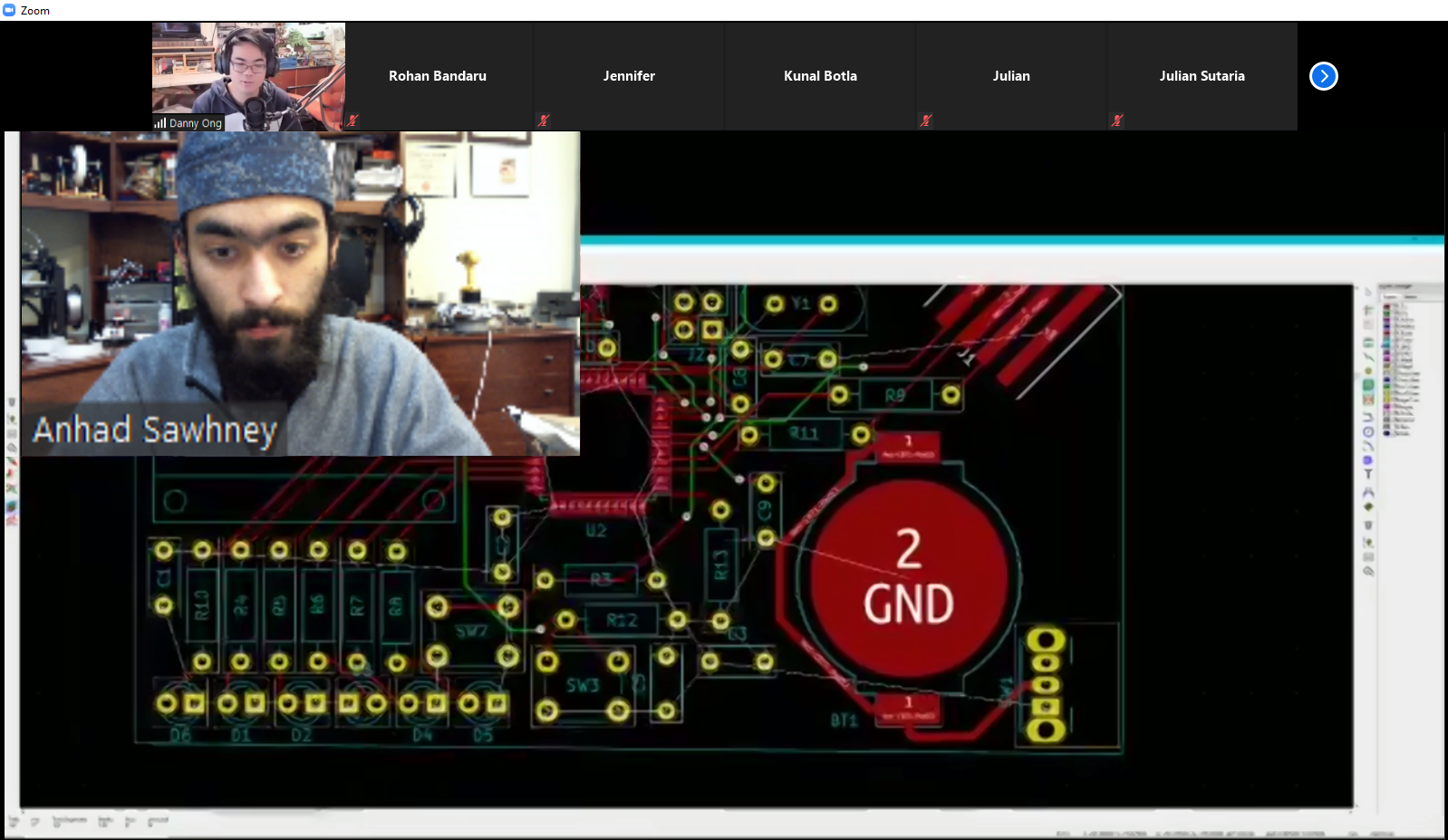

I taught this online class to 12 students from my high school. Printed Circuit Board (PCB) design was a skill I had been wanting to share ever since I learned it, because of everything it has allowed me to create.

I finally got the chance while school was in lockdown. I was able to share my passion for electronics and create a space where we could hang out despite all being isolated.

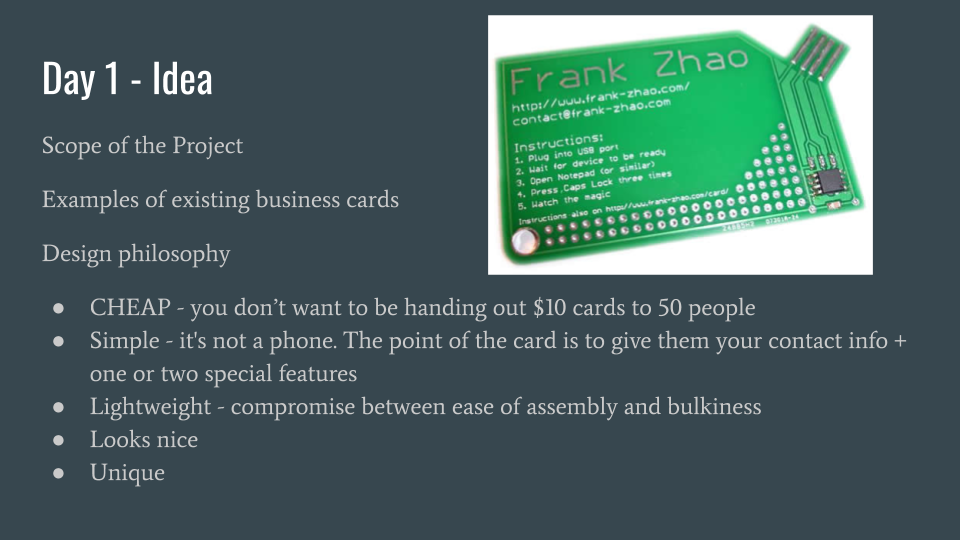

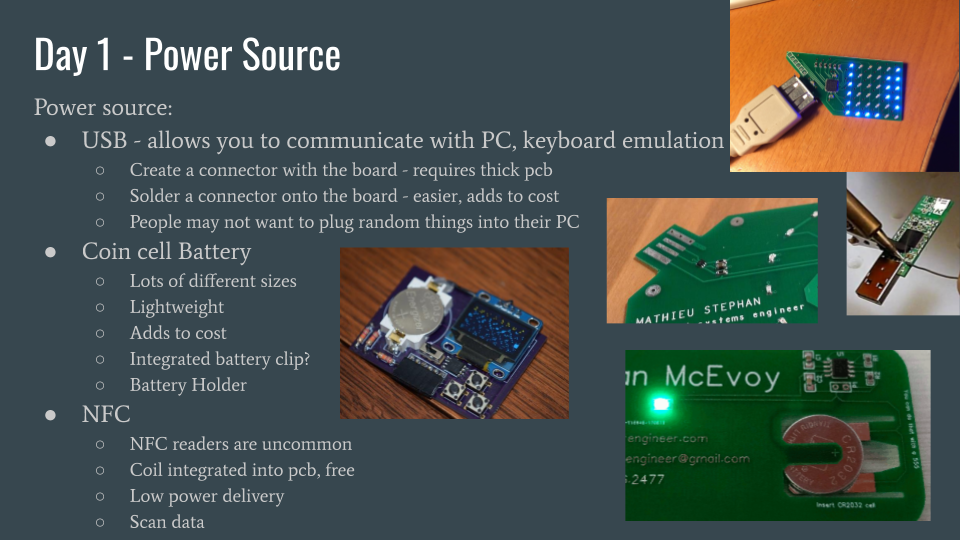

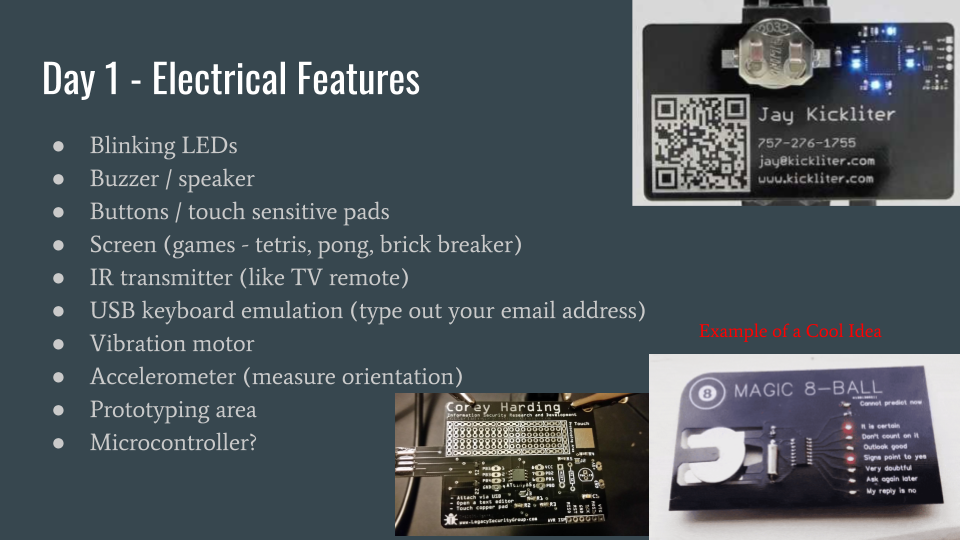

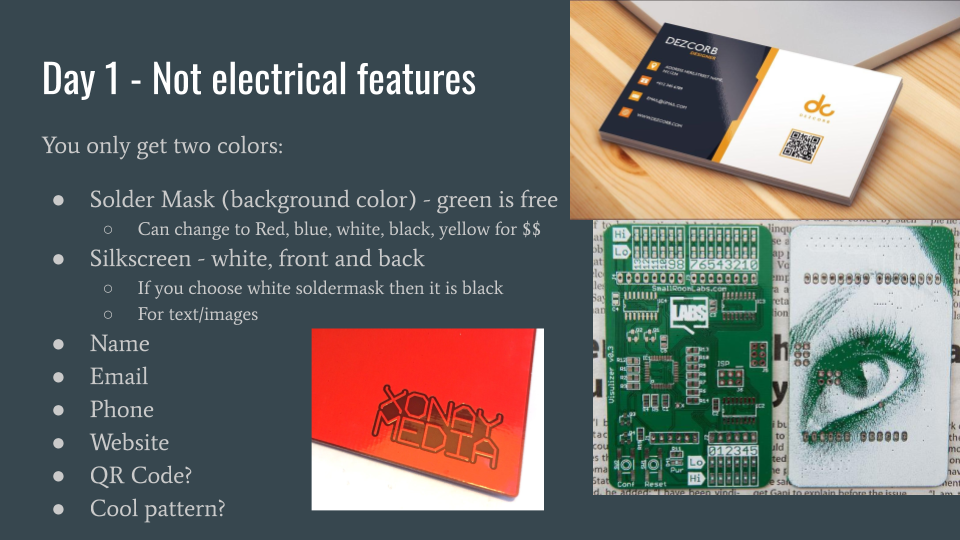

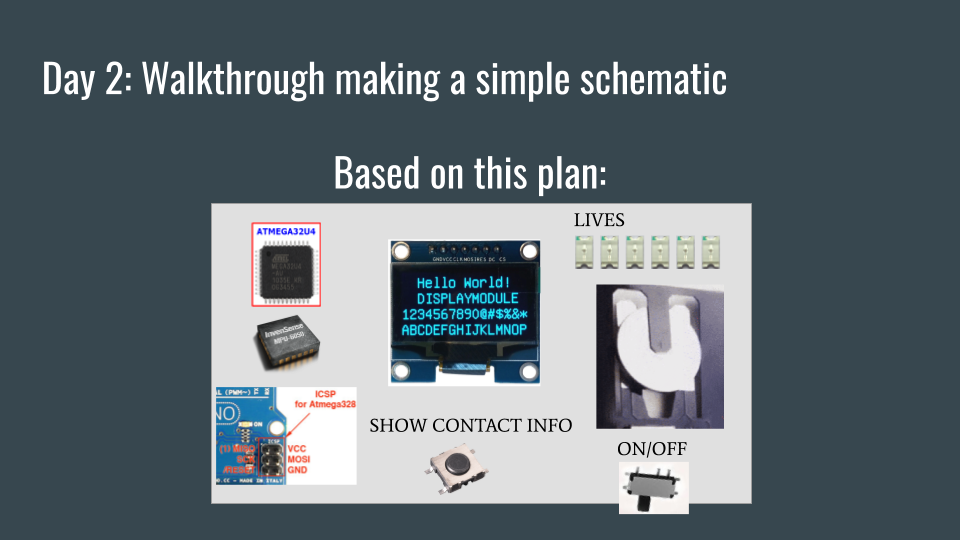

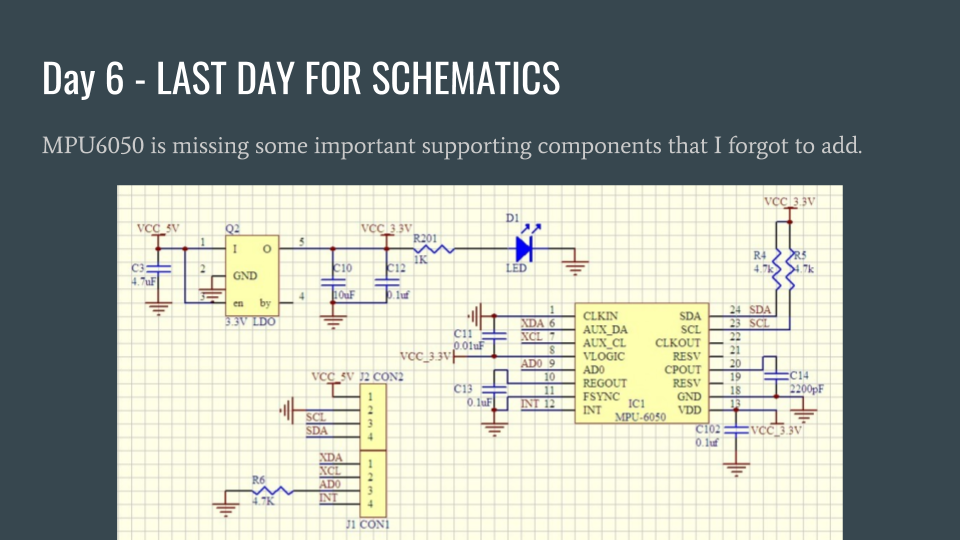

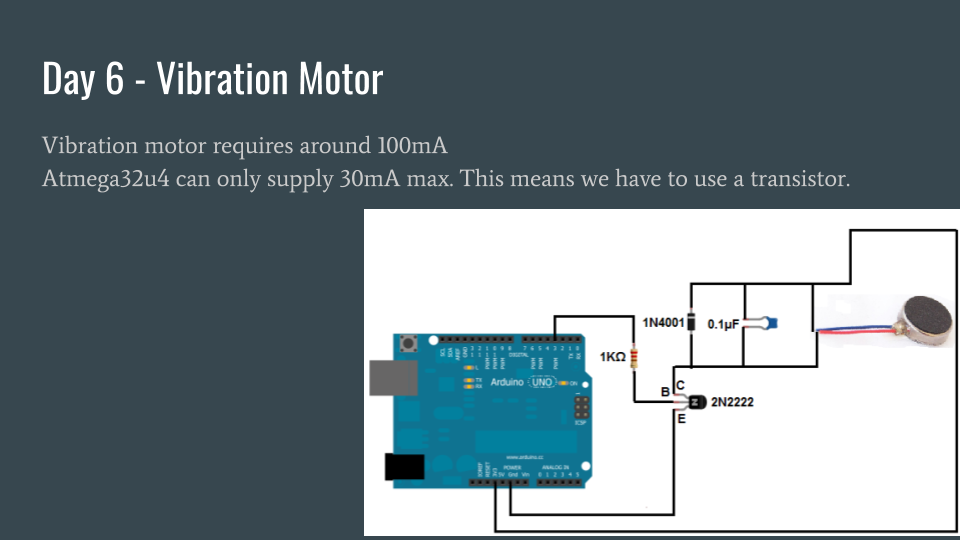

I designed the curriculum for this project using my own self-taught knowledge and free software. The best way to learn a new skill is by using it to build something, so I focused on making a PCB business card. Basically, these were business cards made from circuit boards, with some basic electronic functionality, like batteries, buttons, screens and blinking lights.

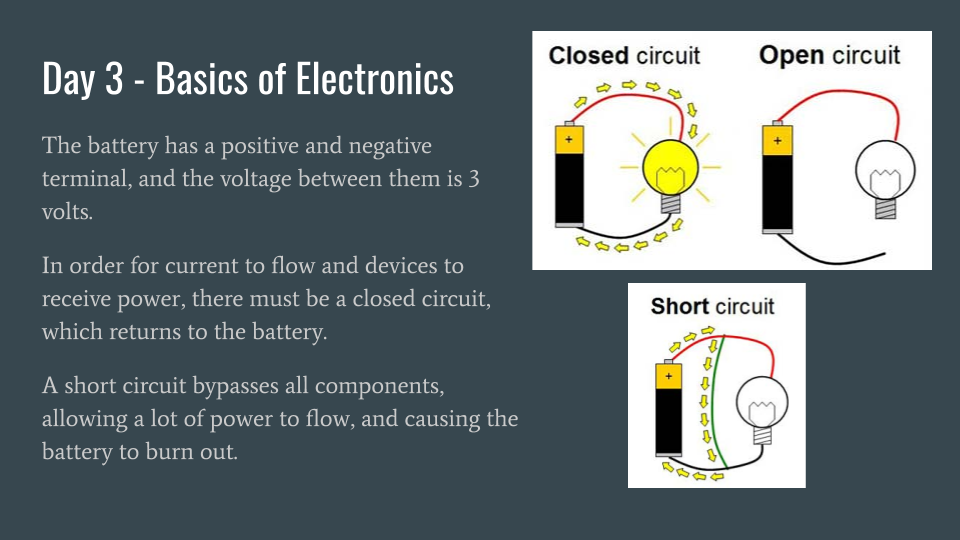

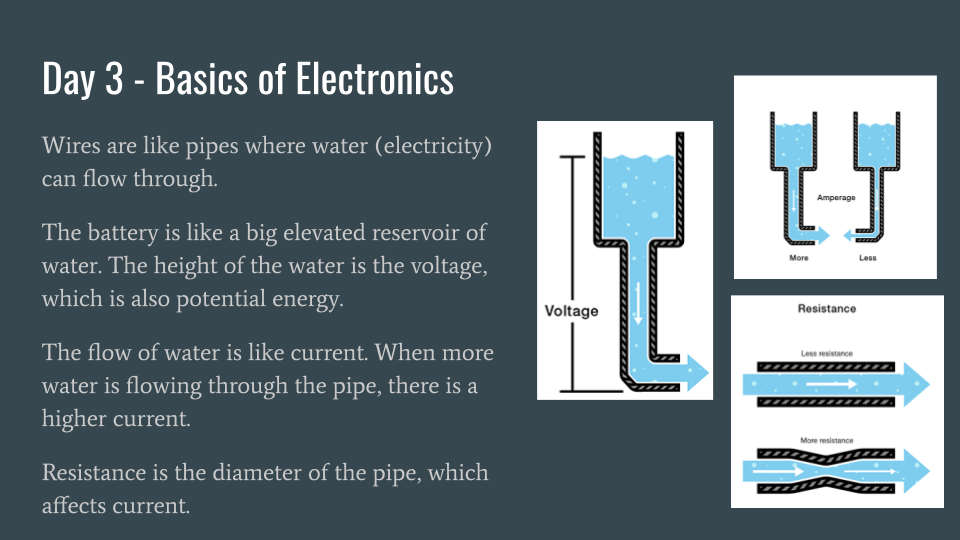

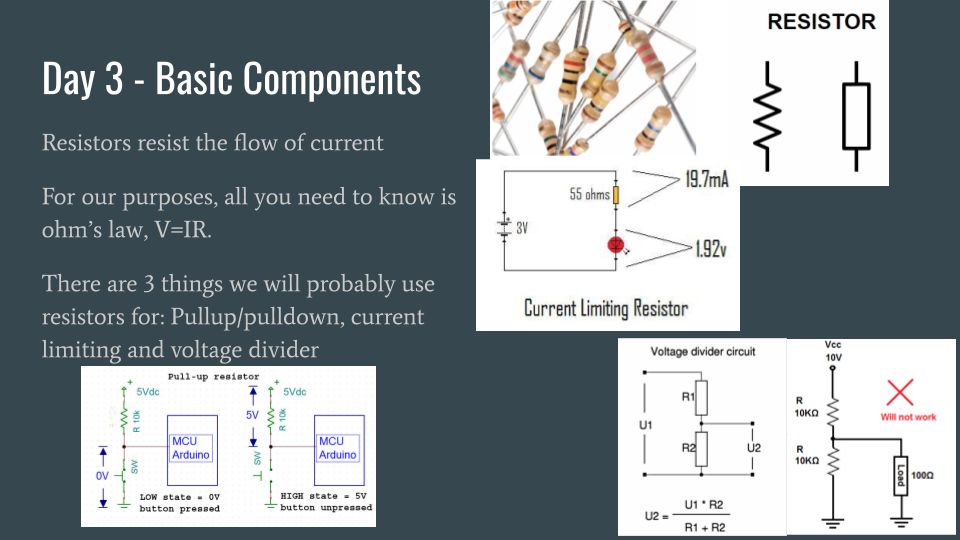

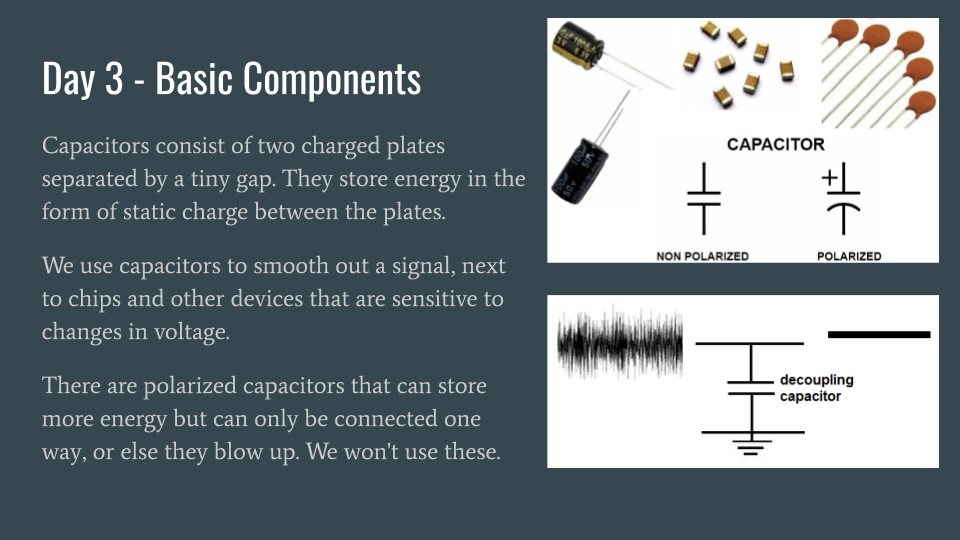

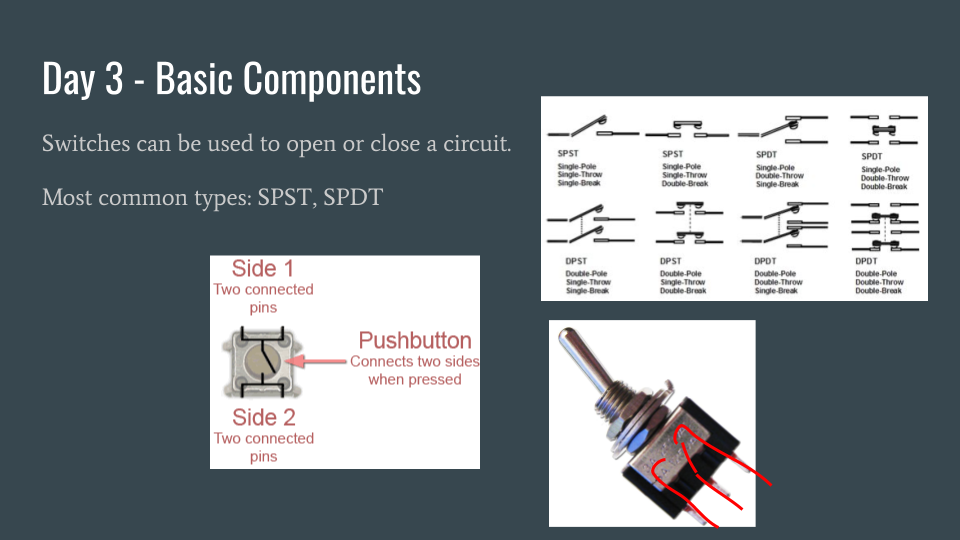

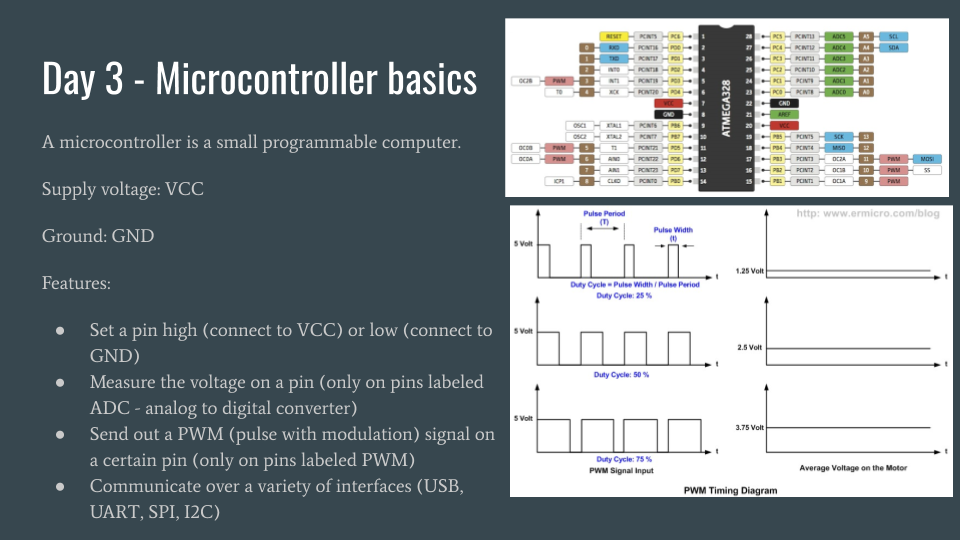

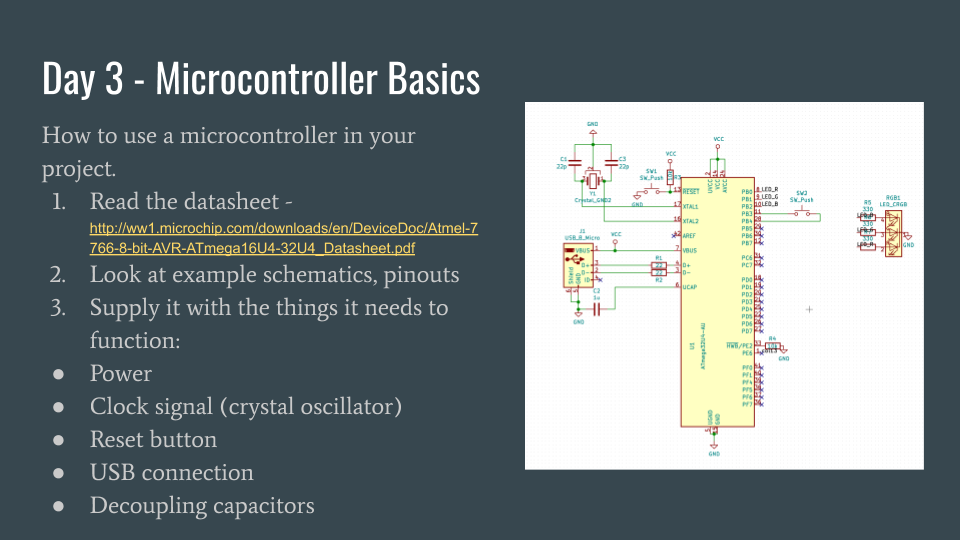

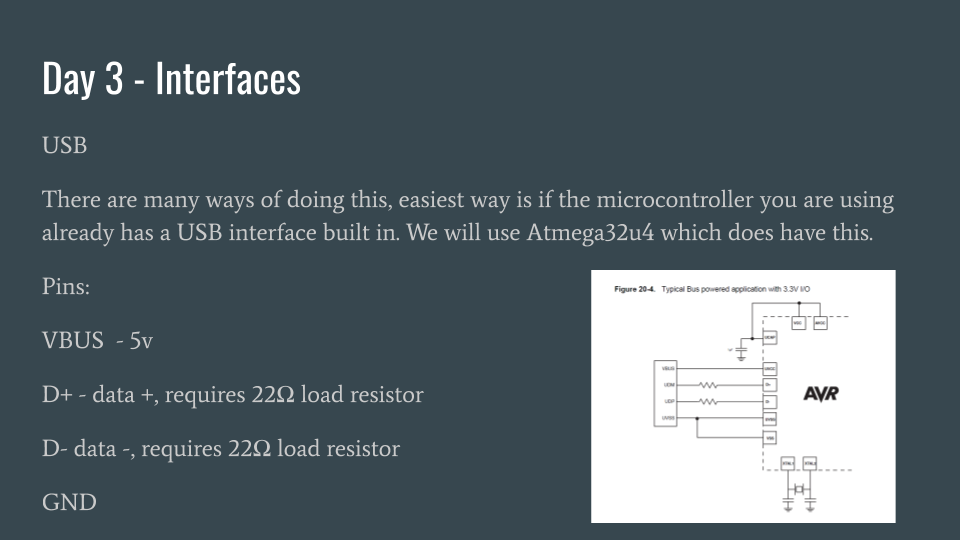

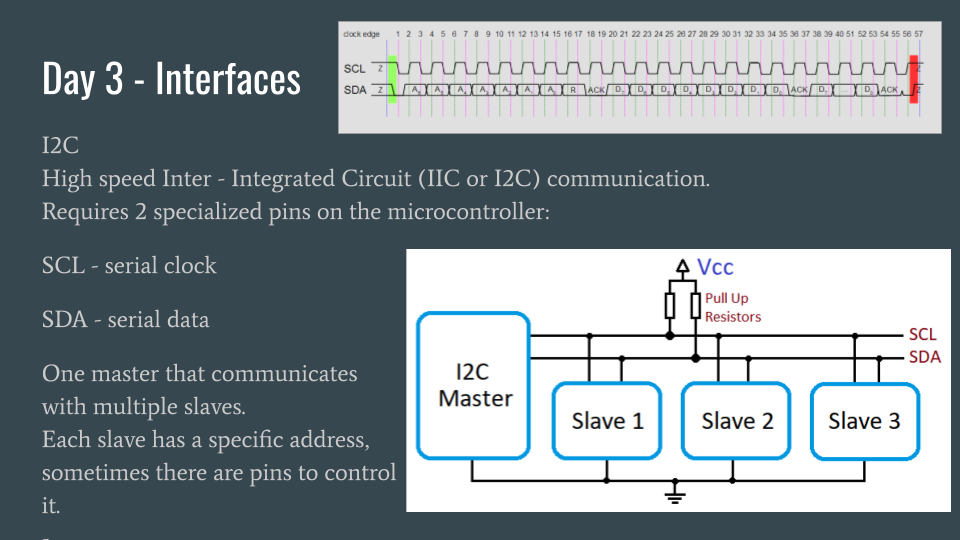

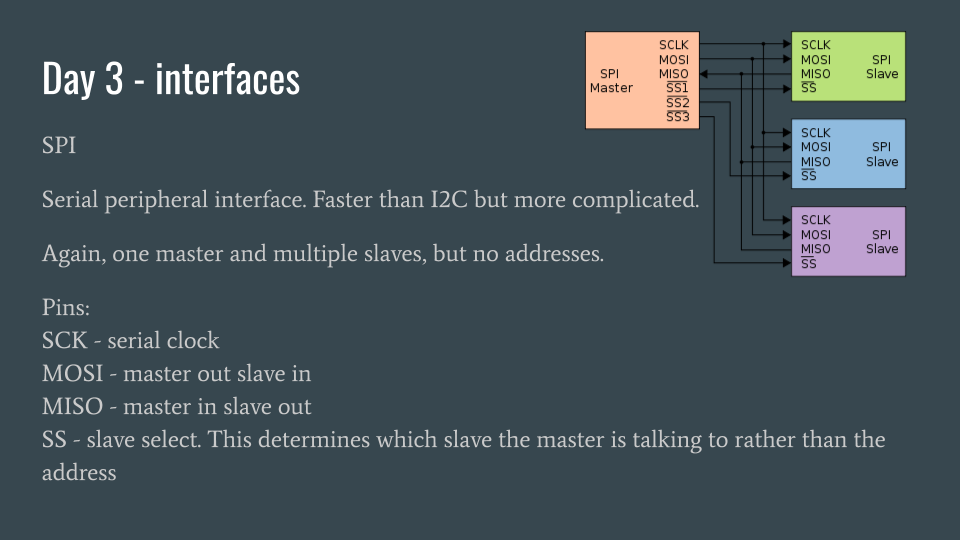

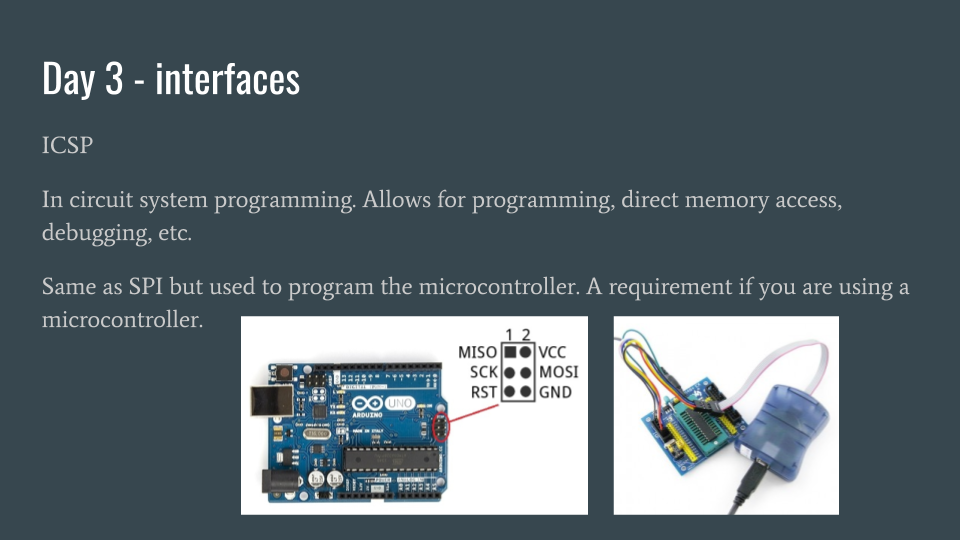

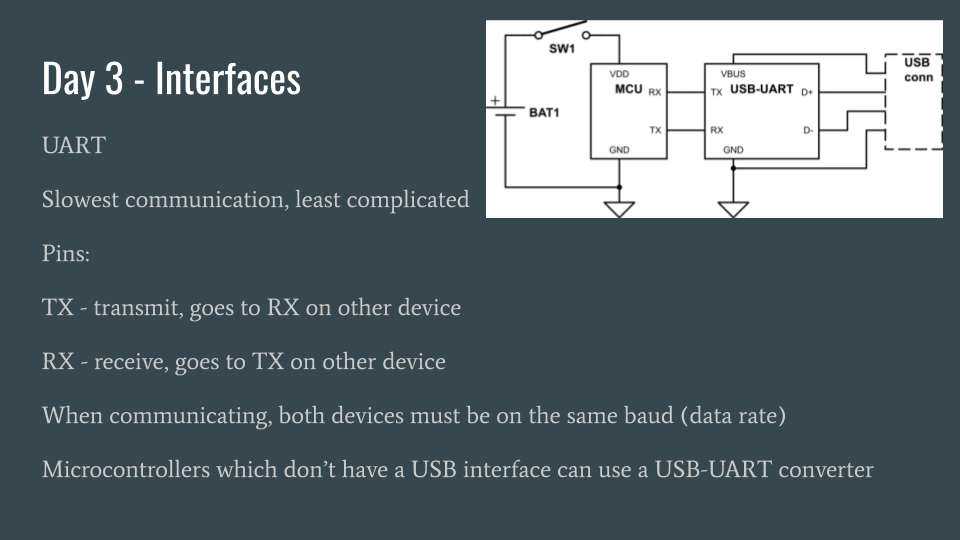

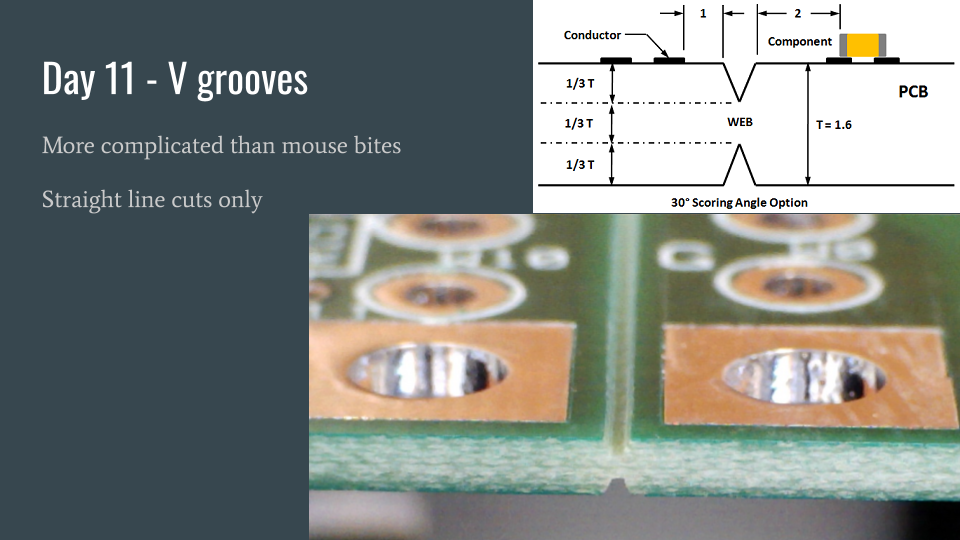

The class took place over Zoom, an hour each weekday for five weeks. I covered everything from Ohm’s law to serial communication. Each meeting, I taught from the slideshow I created at the beginning, and demonstrated the skills by working on my own business card. Then, I helped each student with their specific designs.

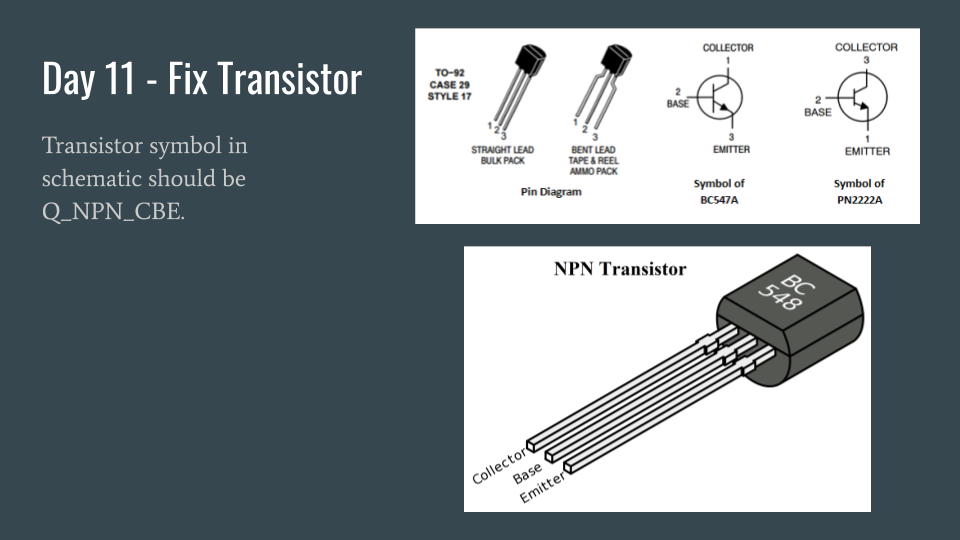

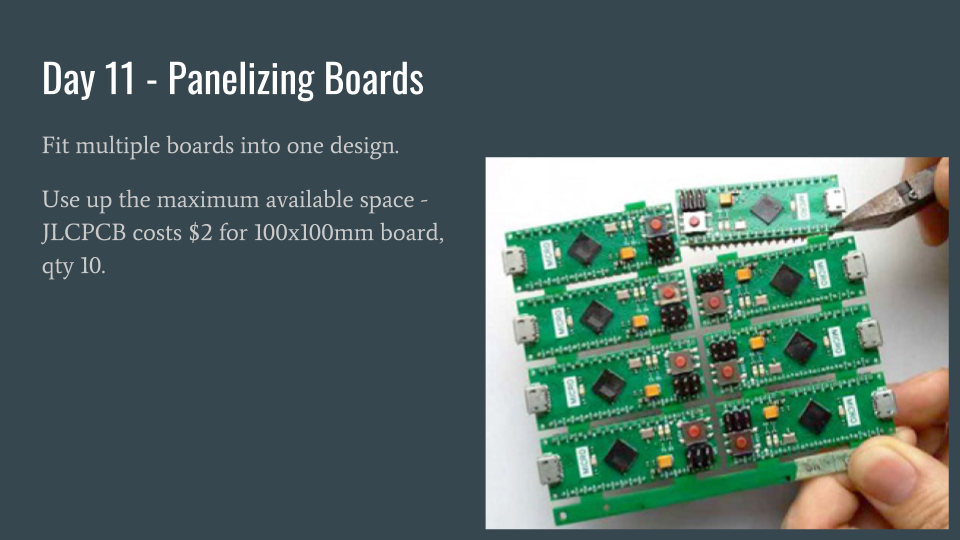

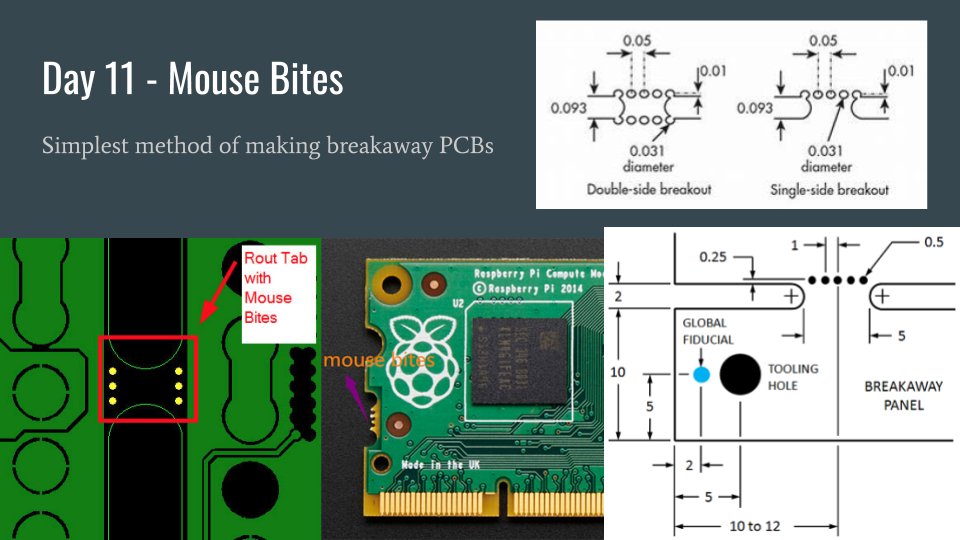

SLIDES FROM THE CURRICULUM I CREATED:

SOME OF THE PROJECTS I HELPED MY STUDENTS CREATE:

I was pleasantly surprised that many of my students chose to go beyond the basic components and skills that I introduced. Some incorporated USB ports and microcontrollers into their design, others added QR codes and artwork to fill the blank space, and one even experimented with wireless NFC communication. Here are some examples the business cards we made (I have censored the personal information):